Vocabulary Terms

Tuesday, May 31, 2011 at 4:57PM

Tuesday, May 31, 2011 at 4:57PM Back Butter- The spreading of a bond coat to the backs of ceramic tile just before the tile is placed.

Base- Creates a transition from the wall to the floor.

Beak- A corner piece for a quarter round.

Beveled- The angle or inclination of a line or surface that meets another at any angle but 90°.

Bisque- An unglazed white porcelain.

Bullnose- Tile piece that finishes off a run of tile. These pieces can also be used to turn a corner vertically or horizontally.

Butt Joint- The act of placing two tiles together closely as to create the smallest grout joint as possible.

Ceramic- Items, including tiles and pottery, made from clay and fired in a kiln.

Cove Base- Creates a right angle transition from the wall to the floor.

Craze- The random pattern of fine lines or cracks on the surface of a crackle-glazed tile.

Diagonally Set- Turning a square tile 45 degrees and setting it with the point touching the already placed tile.

Earthenware- Ceramics made of opaque, slightly porous clay that is fired at a relatively low heat.

Extruded- Tile or trim unit that is formed when clay mixtures are forced through a die of suitable configuration, resulting in a continuous ribbon of formed clay. A wire cutter or similar cut-off device is then used to cut the ribbon into appropriate lengths and widths of tile.

Face Mounted- Tile that is held together on the front by tape or paper. Usually used on mosaics.

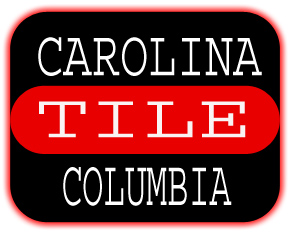

Field- An area of tile covering a wall or floor. The field may be bordered by tile trim.

Fired- The controlled heat treatment of ceramic ware in a kiln or furnace, during the process of manufacture, to develop the desired properties.

Float- To move from place to place, especially at random. Also used as term for tool that spreads adhesive or grout.

Greek Key- A classical pattern of right-angled vertical and horizontal lines that is generally used for borders.

Grout- A rich or strong cementitious or chemically setting mixture used for filling tile joints.

Herringbone- A pattern consisting of rows of short, slanted parallel lines with the direction of the slant alternating row by row.

Kiln- A special oven used to dry and harden clay objects in a process called firing.

Matte- A ceramic glaze having low gloss.

Miter- To cut on an angle so that two edges join without a space.

Molding- Provides a decorative or architectural accent as it finishes off a run of tile.

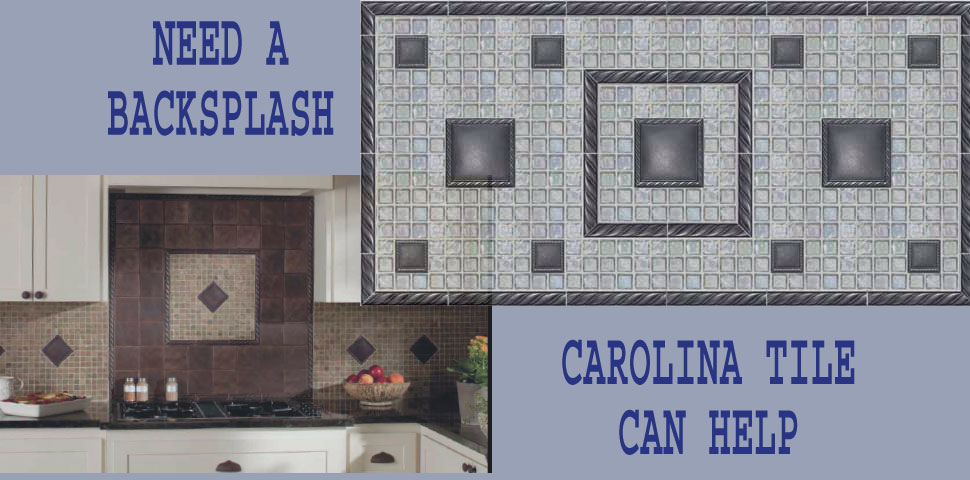

Mosaic- A pattern or picture composed of tiny pieces of stone, tile, glass, or pottery fitted together.

Netted- Pieces held together by a fabric backing.

Pavers- Flat tile or stone blocks designed specifically for use on floors and walkways.

Pillow- cut- A type of tile with edges softly tapered to create a shape like a puffy pillow.

Porcelain- Hard, transparent, nonporous white clay, fired at a very high temperature used for decorative tiles and fine tableware.

Quarry Tile- A tile made from clay that is fired at a very high temperature to make it durable.

Quarter Round- Used to turn a 90-degree corner with a rounded edge either vertically or horizontally.

Relief- A figure or pattern that stands out from the surface of a tile.

Running Bond- Also known as brick bond. A tile pattern that when installed, alternates every other course to make the classic "brick" pattern.

Soldier Course- Oblong tile laid with the long side vertical and all joints in alignment to make a rectangular grid pattern.

Stoneware- Ceramics made of strong, opaque, nonporous clay that is fired at a high temperature.

Terra Cott- A hard molded and fired clay that is used for tile, floor pavers, and sculpture. The most common terra cotta is a dark red-orange, but colors vary depending on the trace elements it contains.

Trim- Finishing pieces of tile that transition two areas.

Trowel- A flat bladed hand tool for leveling, spreading, or shaping substances such as cement or mortar.

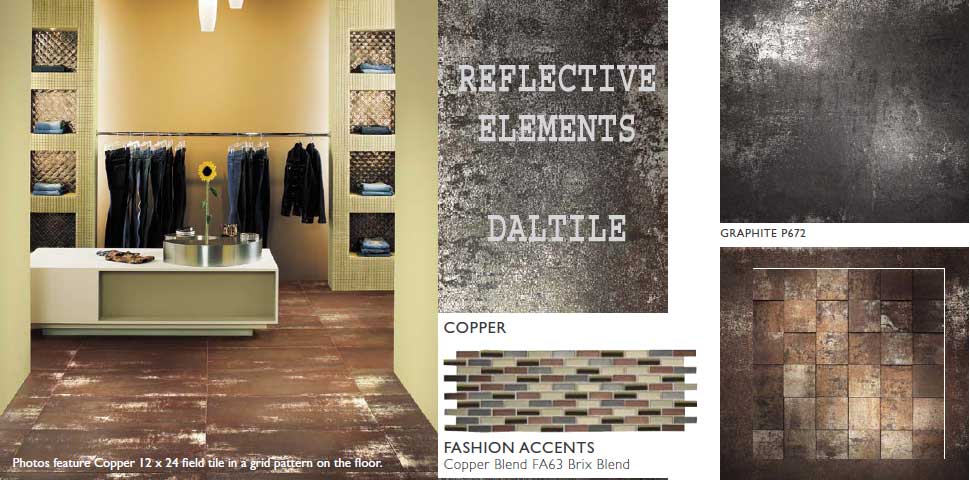

Wainscot- The lower part of an interior wall when finished in a material different from that of the upper part.